Our dorms offer the unique benefit of having full length mirrors on the doors so I figured that suction cups would be the best way to go as they were easy to apply, remove and are non marking.

Being that I already had a Basic Stamp, Parallax's RFID reader seemed to be the obvious choice as it was the cheapest reader I could find and already had example code written for it.

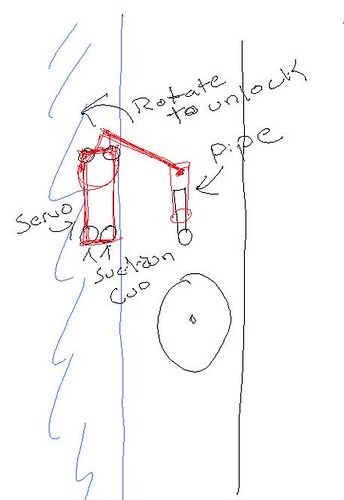

My initial plan involved just a servo, standoffs, and suction cups...

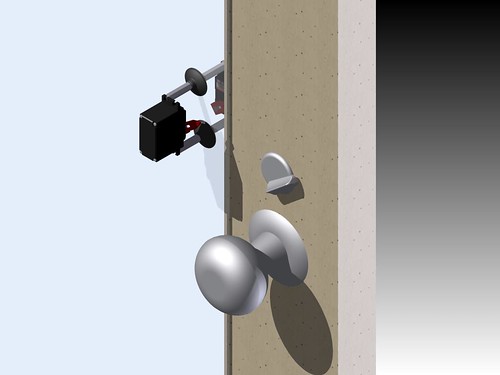

Modeled in Autodesk Inventor...

After some of the parts came in I set up a quick prototype to make sure the servo was even strong enough to flip the latch and that I could read the tag through the door. To attach the servo horn to the latch I tied a piece of string to the horn and taped it to the top of the latch, this is how it done in the final version as well. The reason for using string is so that you could still easily unlock the door with the key, it would just put slack in the string. The only fault with this method is that you cannot use the RFID tag to lock the door.

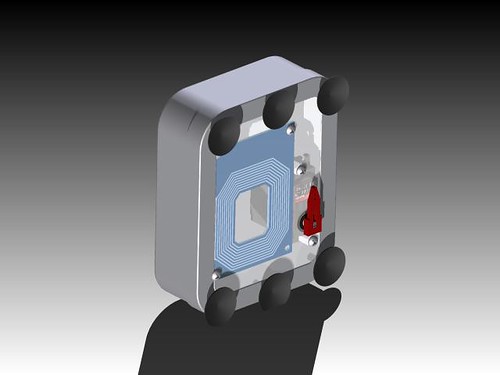

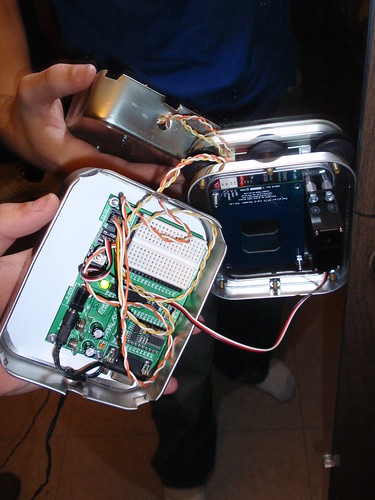

I quickly realized that I had given no thought as to how I was going to mount all the electronics. As a result the servo remained like that on my door for weeks. As I was cleaning my desk one day I found this box and instantly realized that it was perfect for the door unlocker.

Another quick mockup in Invetor to see if everything fit, and it did perectly..

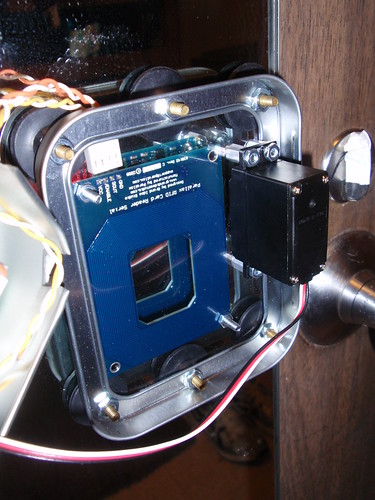

Ordered some 6-32 screws and nuts from McMaster and started assembly.

The servo fits perfectly height wise, it sits against the bottom of the base when closed. Now that I had the servo and RFID reader mounted I needed to get some holes drilled for the suction cups and basic stamp. Due to my

I finally got around to drilling the holes and mounting the whole thing...

I used paper under the basic stamp to insulate it from the metal box.

The assembly did not go without problems, however.

The first major problem was when I went to reassemble the box after I put on the suction cups. I didn't take into consideration that the nuts would get in the way of the box closing. As you can see in the pictures I had to snip spaces in the box where the nuts were so the box would be able to close all the way.

The second major problem was a weird one. The RFID reader was originally going to be mounted on the inside of the box. This box was perfect because the front was plastic and didn't interfere with the reader. The problem was, when I closed everything up in the box the range of the reader was almost cut in half and I couldn't read the tag through the door. However, if I pulled the box apart (like it is being shown in the above pictures) the tag could be read through the door. My best guess is electrical noise is causing this but I honestly did not want to spend any longer on this project, and there seemed little alternatives. I ended up just mounting the reader on the outside of the box. It does not really make any difference other then looks.Here is how it looks when it is all up and running.

The basic stamp program can be downloaded here

While still learning about rdif tags and readers, I do not know of any that are mounted inside of a metal enclosure; mostly plastic and marine plywood. Probably relates to signal reflection or a closed loop around the antenee more than electrical interference from varible frequency.

ReplyDeleteNice locking device, but wary of the range.

My question is how effective are the suction cups? I have used them before in past projects but never for something requiring an absolute position. It seems after a while the box would at best move and not be able to open the door, or at worst fall off the mirror completely...

ReplyDeleteThat being said, nice project!

"My question is how effective are the suction cups?"

ReplyDeleteThe suction cups are actually pretty effective. I too was worried about them staying on there that's why I put six of them. I wet them and cleaned the mirror before I put them on and every few days or so I push on the box to make sure that they are still stuck on there.

what is the pinouts of the connections?

ReplyDeletesorry, found them in the BS file

ReplyDeletethe silvering on the mirror probably effected its range also.

ReplyDeleteIs that Calhoun or Siddall?

ReplyDeleteCan you say "Faraday Cage?"

ReplyDeleteI think its a great idea but your project would be better suited with an acrylic case. It would look much cleaner and I think help with your range issues. Just an idea

ReplyDelete"Is that Calhoun or Siddall?"

ReplyDeleteSiddall, aren't you in my ECE class?

I'm in Digital Systems Design this quarter (15ECEE175, I think) but I'm over in Calhoun.

ReplyDeleteYou can get the ID Innovations ID-12 or ID-20 for less than the paralax RFID reader. They also have a TTL serial output.

ReplyDeleteCheck out: http://www.sparkfun.com/commerce/product_info.php?products_id=8419

The pins aren't 100mil pitch so look at the breakout board too.

You need something more permanent and "cool" on the outside instead of a tiny piece of masking tape.

ReplyDeleteCouldn't the actuator to the lock mechanism be 'stiff' and then be utilized to both lock and unlock the door?

Cool project and implementation!

"Couldn't the actuator to the lock mechanism be 'stiff' and then be utilized to both lock and unlock the door"

ReplyDeleteAgreed

Max, must you always be such a BAMF?

ReplyDeletewhat servo motor did you use?

ReplyDeletecould you show a complete parts list (esp the motor that you used?)

ReplyDeletethanks

I honestly dont know the motor i used but any standard size servo would be perfect

ReplyDeletehttp://servocity.com/html/hitec_servos.html

http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/rfid/List/0/SortField/4/ProductID/114/Default.aspx

http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/rfid/List/0/SortField/4/ProductID/503/Default.aspx

suction cups are from

mcmaster.com search for "Rubber Suction Cups" and they are bottom of the page

the metal box i had lying around and the bolts/nuts/standoffs are all from mcmaster also

Which particular servo did you use?

ReplyDeleteIn order to use the antenna inside the box (with one side open of course) you will need to re-tune it, because the metal is acting somewhat like a slug to an inductor, and it's changing the inductance that the rest of the antenna circuit is built for. There may also be some near-field effects, but tuning is probably the issue. Although it doesn't look like your antenna is readily tunable.

ReplyDeleteDon't feel bad: half of the people who design RFID OEMs haven't figured out how to build good antennas, either.

Cute its really very cute, and i think its a very unique and interesting fashion also, ladies can enjoy this fashion, i like it much.

ReplyDeleteSell used goods

Mechatronics FTW :)

ReplyDeleteI am very thankful to you for posting such stuff.This really help me lot

ReplyDeleteThis blog post is really great; the standard stuff of the post is genuinely amazing.Star Locksmith

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteI read your blogs regularly. Your humoristic way is amusing, continue the good work!The Key Guy Mobile Locksmith

ReplyDeleteThanks for the entire information you have given here to impart knowledge amongst us?http://www.thelocksmithbirmingham.co.uk/

ReplyDeleteI am confident you've got a great enthusiast following there.Right Away Locksmith in Chicago IL

ReplyDeleteI will make sure to be reading your blog more. You made a good point but I can't help but wonder, what about the other side? THANKS!

ReplyDeleteSerrurier sur Chelles

Mostly the task of unlocking a door isn't a hard task but sometimes when your locks need repair it can turn into a nightmare. You can easily piece together an RFID lock which unlocks with a wireless key and can lock itself automatically. Locksmith Fort Lauderdale provides advanced and secure locking systems for your home.

ReplyDeleteTo repair or open the locks you need tips, tricks and tools for this. This can't be done by own if you don't have such things with you. Locksmith are those persons who have all those things with them and they have experience of unlocking and repairing the door locks.

ReplyDeleteDoes Ufone Have 3G Coverage In khanpur?

ReplyDeleteDoes Ufone Have 3G Coverage In khanewal?

Does Ufone Have 3G Coverage In kasur?

Does Ufone Have 3G Coverage In kharachi?

Does Ufone Have 3G Coverage In Kamoke?

Awesome,

ReplyDeleteThank you so much for sharing such an awesome blog...

door interlock system

boom barriers

boom barrier gates

Useful Information, your blog is sharing unique information....

ReplyDeleteThanks for sharing!!!

tyre killers in chennai

solar electric power fence in chennai

sliding gates in chennai

automatic gates in chennai

hydraulic rising bollards in chennai

electric door strikes in chennai

Solar power fence in chennai

ReplyDeleteThank you so much for sharing such an awesome blog...

electromagnetic locks suppliers

electromagnetic locks manufacturers

electric door strike

Very nice blog to show how to create a automatic door system. Thanks author for sharing the post. Keep doing good works.

ReplyDeleteinstagram search

Good article! Thanks for sharing. The last announcements about timber windows and doors. Look here. Housing info on this site

ReplyDeleteПривет! Рекомендуем справочник используемых медпрепаратов. В путеводитель включены сведения о почти семистах современных медикаментах, производимых отечественными и иностранными фармкомпаниями. О любом препарате имеется подробнейшая информация: состав и форма выпуска, лечебные характеристики, показания к использованию, правила эксплуатации, вероятные побочные эффекты, взаимодействие со спиртным, противопоказания и взаимодействие остальными лекарствами, кроме того возможность назначения при грудном вскармливании, беременности. В путеводитель включен тематический указатель, в котором имеется инфа о том, какое лекарство необходимо применять при тех или иных болезнях, состояниях, синдромах. Путеводитель опубликовано на мед ресурсе. Если не поможет, обратитесь к доктору. Дифеноксилат / атропин, Альбумин, Ломустин, Делавирдин, Аммония карбонат, Изоконазол,

ReplyDeleteРаздвижные окна и двери, иначе называемые PSK-порталом, монтируются намерено для экономии свободного, незаполненного пространства. Нормальные виды открываются внутрь помещения, что занимает достаточно большую часть места в помещении. Современные окна разрешают избежать этой трудности, увеличить световой и воздушный поток в помещении.

ReplyDeleteПортальные окна и двери – это системы, что обладают широкой площадью остекления. Для обеспечения возможности открывания створок присутствуют нижние и верхние полозья, благодаря которым створка легко и бесшумно движется.

Раздвигание происходит с помощью ходовых роликов, что содержат опору как элемент армирования, дающим возможность максимально равномерно распределять вес по по всему окну. Они дают возможность створке окна передвигаться во всевозможных режимах (сдвига, наклона).

Высота окна или двери должна быть не более 2360 мм, а ширина створки может меняться от 670 мм до 160 см. С учетом общего веса (варьируется от 100 кг до 200 кг), на параллельно-раздвижную дверь монтируется определенная фурнитура ради обеспечения исправного открывания - закрывания створок, продления срока функционирования. Ширина свободного проема имеет возможность достигать 2 метров.

Параллельно-раздвижные окна и двери могут похвастаться хорошими герметичными качествами, хорошими показателями звуко-, термоизоляции, предлагают должный уровень противовзломности, замечательно подходят для всех видов нынешних профилей. При сборке применяют опоясывающие щеточные уплотнители, кои заметно оптимизируют работу створок.

В случае, если вам хочется оформить балкон, городскую квартиру, лоджию или большой загородный дом согласно модным тенденциям в стиле, то компания-производитель СВ Окна сделает и установит параллельно-раздвижные окна и двери.

Редкие фирмы-изготовители косметических препаратов могут похвалиться тем, что их товар попал в разряд победителей, которые предпочли члены королевских династий. Компания Lebel Cosmetics уже более трех десятков лет поставляет собственную продукцию в японский императорский дом. Неудивительно, что, заслужив титул косметики №1 в Японии, линия фитоламинирования волос Лебел в салоне красоты без усилий захватила рынок Европы и уже покорила сердца большого количества девушек стран Северной Америки.

ReplyDeleteServing the clients with utmost satisfaction and value since 1953, Garg Locks has been estimated as a highly known Manufacturer of Door Locks. Conceptualized with an attitude to serve a huge custom our high-quality range of products includes Door Locks. Garg Locks will align itself with manufacturers known for cutting-edge technology and high-quality at reasonable prices.

ReplyDeleteA locksmith Atlantis ensures your security with comprehensive services.

ReplyDelete